Main characteristic of Grip coupling

发布日期:2013-07-09

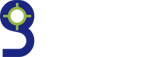

Pipe coupling with different pipe diameter, nominal pressure: 0.2 ~ 1.6 MPa maximum allowable working pressure: 0.3 ~ 6.7 MPa, the maximum allowable medium temperature: 100 ℃, suitable for all kinds of connection of pipe system.

Advantage:

In 0 ~ 2.5 MPa stamping fatigue test under pressure, product can withstand 12000 pulses without the tube body damage

Pipe coupling of the rubber sealing packing structure design can ensure the tube medium run smoothly, avoid to produce electrochemical corrosion at the same time, in order to guarantee the service life of the device.

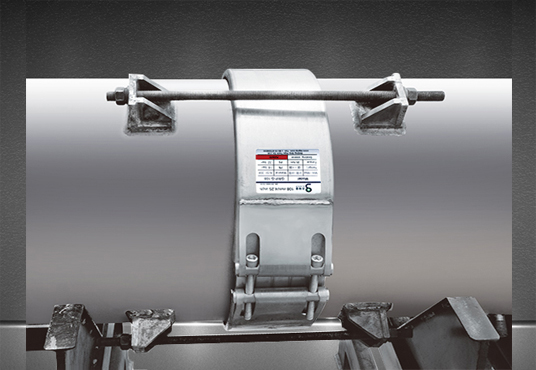

Shock absorption, noise reduction, resistance to impact

Pipe coupling adopts flexible joint method has the effect of damping noise reduction compared with the traditional rigid joint tube body. At the same time, compared with the traditional flange connection, as product receives instant impact, noise intensity decreased significantly. In addition, this kind of connection mode is beneficial to the whole pipeline system on the service life of pumps, valves, instrument

Reduce the weight

Compared with the flange connection of the tube, pipe coupling connection method gets significant weight loss. For example: only 3000 (size: 48.3 ~ 219.1 mm) pipe conupling per ship use, can reduce the total weight of 24 tons. The design of the light weight can reduce more extral pressure to the pipe line system.

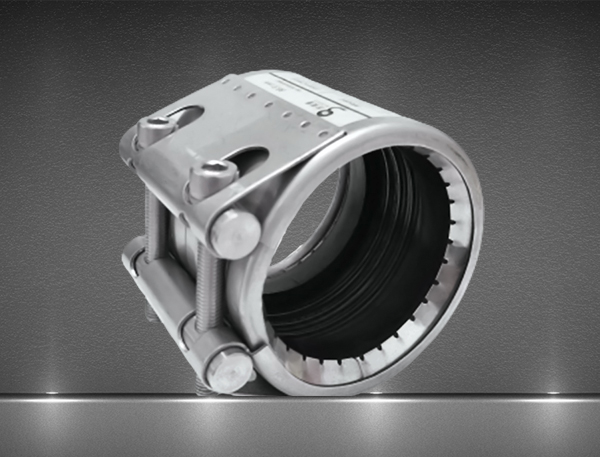

Traditional fixed flange connection mode needs more space to fix pipes. Pipe cuopling installation needs only a side position to install to save design and construction space.

Compatible with good adaptability

Pipe couplings are suitable for all kinds of metal pipe or non-metallic pipelines. There is no special requirement for medium or pipe wall thickness . When two pipe axis deviation is less than 3 mm, in nominal pressure (1.6 MPa),there is no leakage between connection point. In single pipe migration 4 °, at 5 ~ 35 mm tube spacing, pipe coupling connection can still apply to the modern technology under the condition of high assembly accuracy requirement.

Installation is convenient and feasible

On-site installation pipe connection, product only need to use torque wrench, is according to the torque requirements, from single connection 1 ~ 2 bolts, operation is simple and feasible.

When pipe is in repair, double cassettle pipe connection patch and folding pipe connection patch not only use for conventional conditions, but also use under the state of oil and water pipeline installation in order to avoid potential fire and explosion hazard from welding method.

Computer aided design to improve the design of product reliability

The use of computer aided design method is different from the structure of the flange hole. The design process is easier and faster. This method also improves the reliability of the product in order to save the cost of design.